MPI Testing

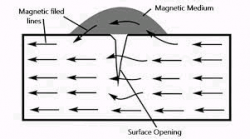

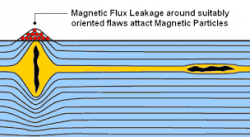

Magnetic particle examination or Magnetic particle inspection is a popular, cost-effective method that is used to facilitate non-destructive examination (NDE) involving ferromagnetic (any material that is capable of magnetization or those highly attracted by magnetic fields) objects.

This method is used to detect surface as well as subsurface ferromagnetic discontinuities existing in materials like:

- Cobalt

- Nickel

- Iron

- Other alloys

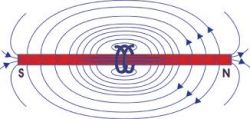

The magnetic particle examination process involves placing a magnetic field into action. Test objects can become magnetized by direct or indirect magnetization. In cases of direct magnetization, the electric current travels through the material being tested, and a magnetic field builds in that object.

Indirect magnetization takes place when there is no current passing through the material, but a magnetic field is applied from an outside source.

There are many techniques involving magnetic particle examination, and the most recognized magnetization techniques include:

- Longitudinal magnetization

- Prod technique

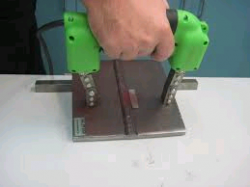

- Yoke technique

- Circular magnetization

- Multidirectional magnetization.